Our Mission

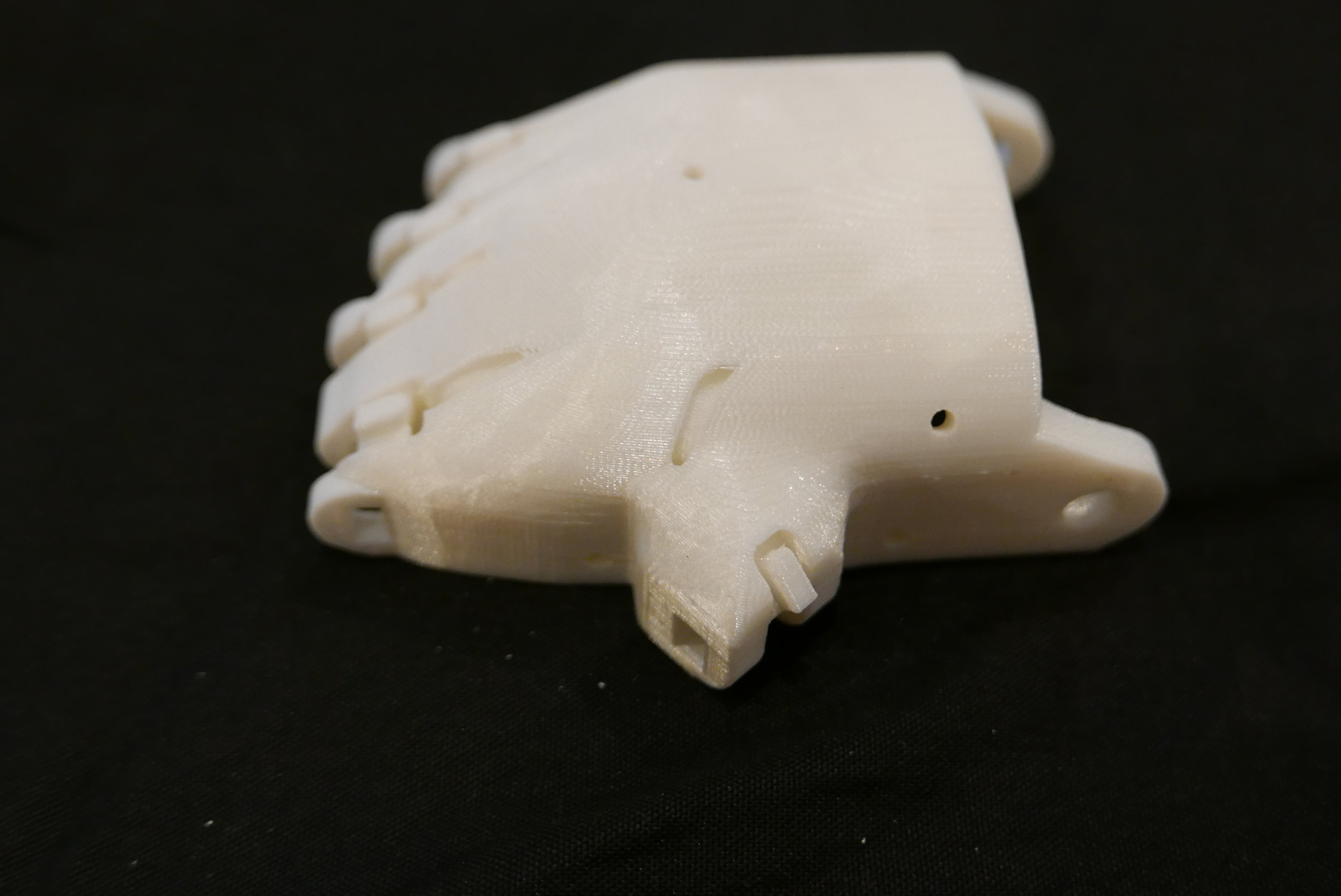

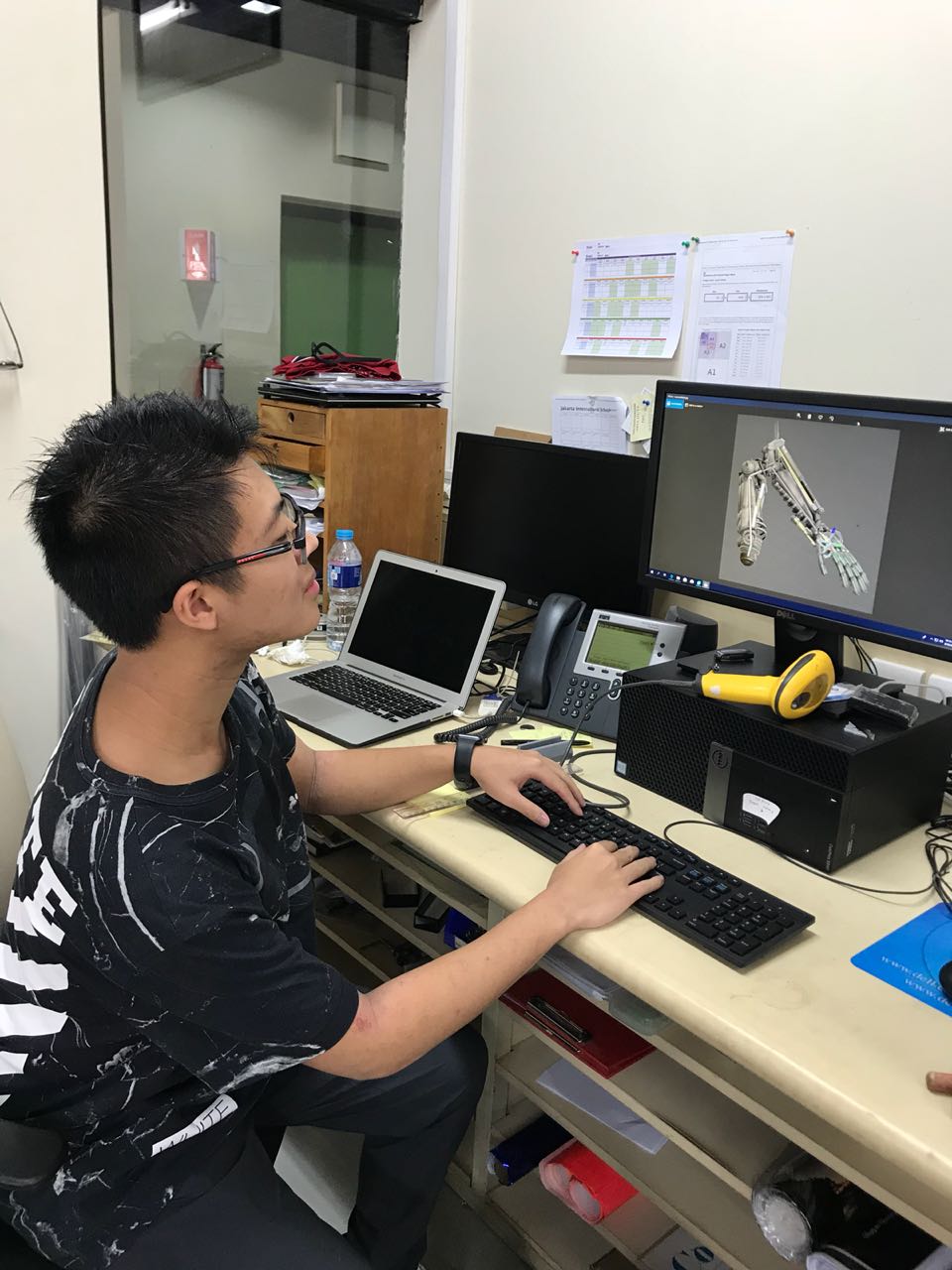

Limbcarnation Prosthetics is a non-profit organization, founded in 2017, created to design and supply prosthetic devices free of charge to those in need. We use 3D printing technology to build prosthetics parts that are virtually adjusted and custom-fit to the specifications of our patients.

Our vision is to combine and use our interest, knowledge, and strength in Physics, Chemistry, and Computer Science to help the disabled and contribute to our the community. Our team consists of a diverse group of students who go above and beyond to make a difference.

Who We Help

We use 3D technology to produce custom-fit prosthetic devices to impoverished children in Indonesia with missing limbs, who need frequent replacements as they continue to grow. With our 3D printed prosthetics, children gain use of their hands, arms, and legs, in their everyday lives.

We also make prosthetics for Indonesian low-income adults – our devices can alleviate physical discomfort and assist with gaining employment. On a case-by-case basis, we may ship our prosthetics for people of all ages internationally.

OUR BUSINESS MODEL

Besides donations, we also employ a one for one business model: for every 3D-printed prosthetic bought, we make a second one and give it to a patient from a low-income family who needs it.